Product Video

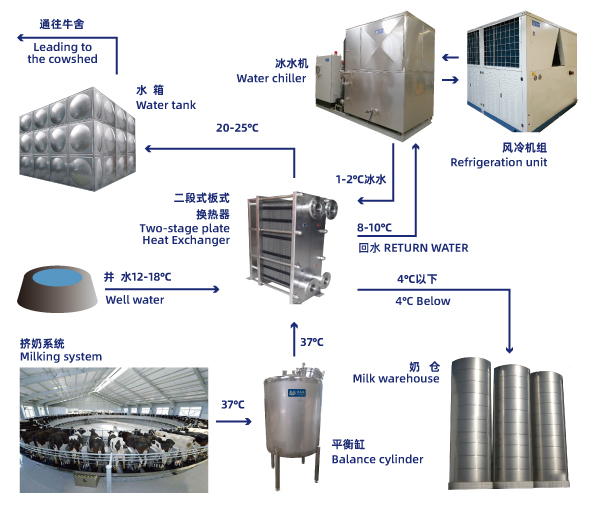

Milk cooling system used in dairy farm

Milk cooling system advantages

System safety, energy saving

No need to add antifreeze in the water, and the evaporator has no risk of bursting.

Modularity design

Modular design, compact structure, easy for installationand maintenance.

Automation

Control system is Industrial-grade programmable controller(PLC),the user only need to press one-button to start and the degree of automation is high.

Remote real-time monitoring

Refrigeration system can be remotely monitored in real time, you can remote monitoring of the chiller through computer or mobile phone, we have our own App, it is very convenient for you to know milk temperature and equipment running situation.

Reliable backup system

It has compressor and water pumps for backup, during the milking process, any compressor unit fails, and the remaining unit can cool themilk to below 4℃,which does not affect the normal milking, have enough time for maintenance.

Picture on site

Milk collection heat exchange module

Milk colection system is composed of balanced milk collection function,heat exchange function,and CIP automatic cleaning fuction.

Function summary:

The balanced milk collection function is a fully automatic frequency conversion milk collection. There are two-stage heat exchange, the first stage use well water for pre-cooling, and the second stage use chilled water for deep cooling. CIP cleaning is fully automated, mainly for cleaning balance cylinders, milk pumps, heat exchangers plate and pipeline valves.

Advantages:

Frequency conversion milk to reduce bacterial reproduction.

Two-stage heat exchange, reduce energy consumption, and greatly reduce the cost.

Efficient and easy for cleaning.

Modular combination, simply and clean on site

Water chiller module

You can choose falling film chiller or ice bank. Ice bank apply for small and medium dairy farm a group of 500 to 2500 cows .Falling film apply for large dairy farm a group more than 2500 cows. Depending upon your requests, our engineers give optimal solutions for you.

Ensure cooling effect is achieved and the energy consumption is minimized.

Control module

The control module is composed of a refrigeration unit control system and a milk collection heat exchange control system.

The refrigeration unit control system has fully automatic control functions, remote real-time monitoring functions, various protection functions, and touch screen display functions.

This system has fully automatic frequency conversion milk collection control function, fully automatic CIP cleaning control function, remote real-time monitoring function, monitoring and recording milk temperature function.

Refrigeration unit module

This module generally adopts the air-cooled integral unit .Units generally choose use 2 and 1 for spare or use 3 and 1 for spare. In the process of milking, any of a compressor unit fails, the remaining units can down the milk below 4 ℃, not affect the normal milk. Have enough time to repair the unit.